JS-1825ST-SCCD-AUTO

- Large working area laser cutting system.

- Automatic edge finding panoramic camera positioning and cutting.

- It supports cutting at any angle with high cutting precision.

- Automatic vision recognition software running.

- Automatic material feeding,cutting any type of textile.

- Save a lot of labor and materials,7-8 cutting workers replaced.

Product Description

Big vision automatic contour extraction cutting, camera positioning cutting, digital printing cutting, clothing fabric cutting, automatic feeding laser cutting machine

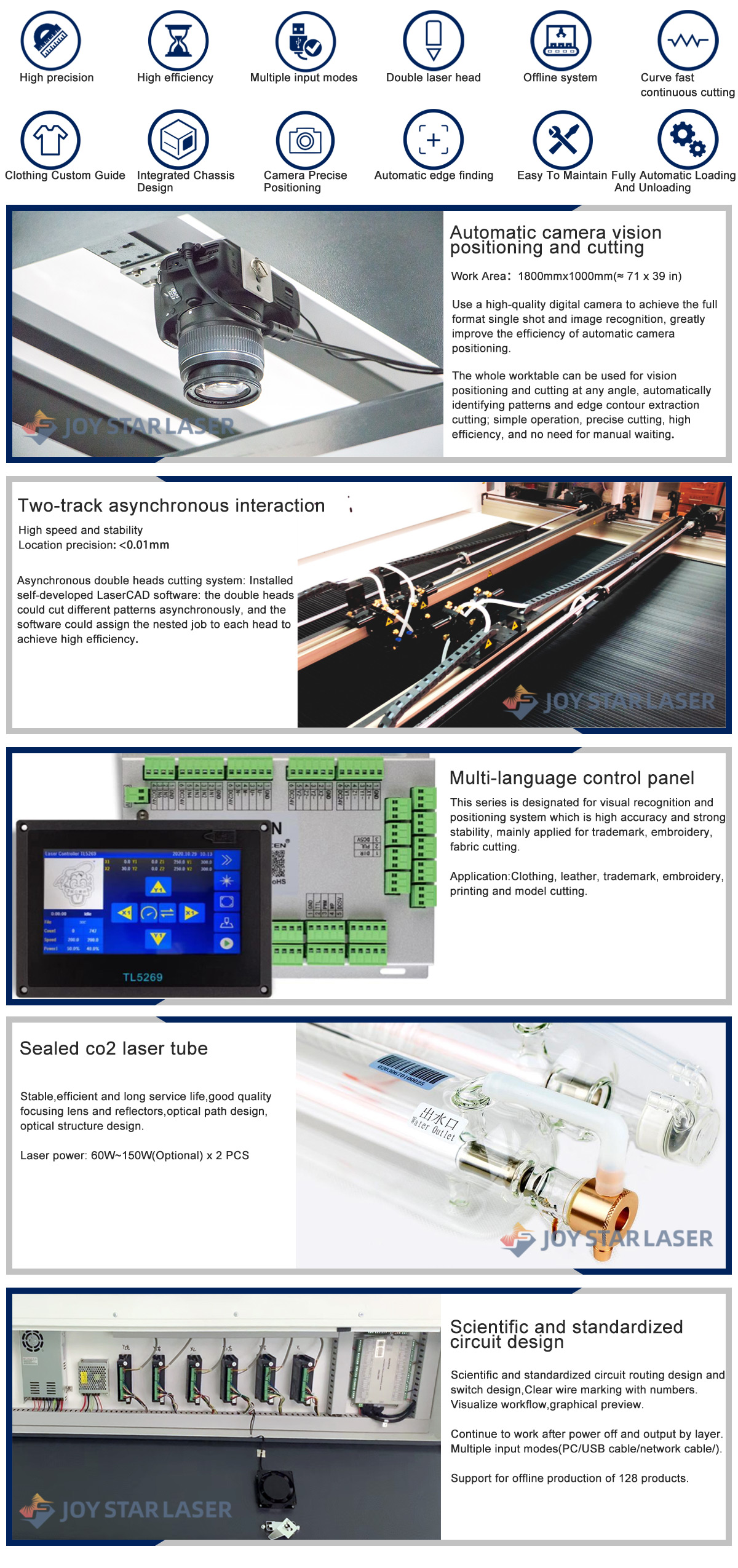

Asynchronous double heads cutting system: Installed self-developed LaserCAD software: the double heads could cut different patterns asynchronously, and the software could assign the nested job to each head to achieve high efficiency;

Large format vision cutting system: support printed material contour extraction, support maximum 9 different templates matching and processing;

Projection function: nesting and collecting by projection, the projected image shows different sizes, different components, left right patterns. It has convenient nesting and collection function;

Auto-nesting software: The nesting system could nesting in high utilization rate in a short time. The advantages of automatic typesetting can support automatic nesting to double as a unit, also support one foot of row material, mixing, scrap cutter;

Fully enclosed laser path design, comply with CE safety certification.

Use a high-quality digital camera to achieve the full format single shot and image recognition, greatly improve the efficiency of automatic camera positioning.

Support the full format image automatic recognition and generate the contour template, or customize a few graphical templates. The software will match the feature template with the material, and send the data to the motion controller to achieve fast and accuratepositioning and processing.

Support to set camera calibration offset compensation, and correctthe overall offset after the device has been running for a period oftime to ensure the precise cutting.

Intelligent all-round camera vision system;for the recognition of larger patterns to achieve precise recognition,different shapes of patterns can be recognized at the same time,the system can automatically generate cutting paths,simple operation.

Itsupports full-frame automatic recognition of image contours,generation of templates and custom drawing of multiple graphic templates.Pieces are matched to the entire page according to the characteristics of the template to achieve rapid and accurate positioning and processing.

The parameters can be set directly according to the material thickness for cutting,and the operation is simpler.

Product parts advantages

Optional

Our products can be selected according to the customer's work needs.If you want more details,contact us please!

The main parts of our products are high-quality industrial-grade accessories.Laser head will make effect of engraving and cutting better.High speed and high precision. Don't need to install extra work software,and it has multi-language function.

✦Optional number of laser heads, two heads (default), four laser heads or six laser heads.

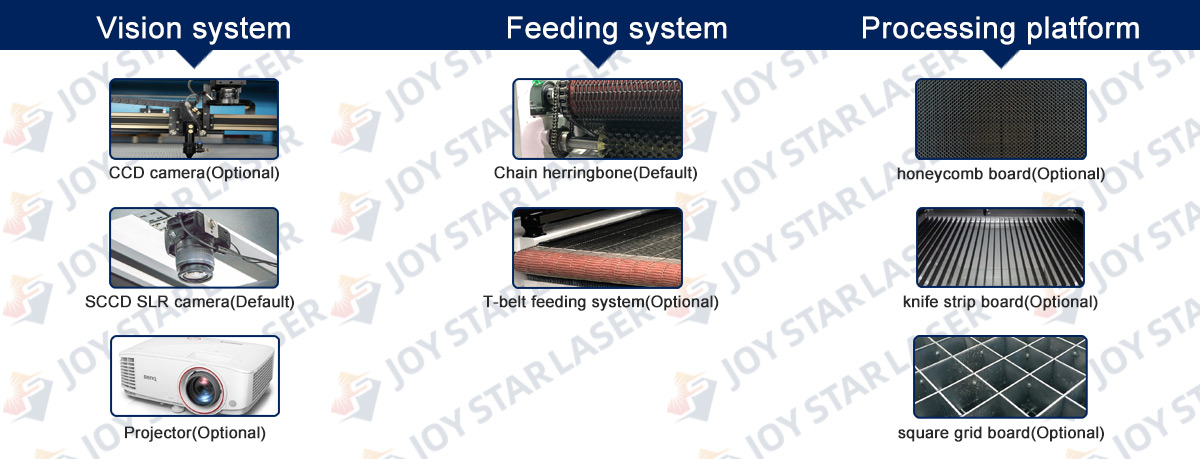

✦Optional super camera/camera:

According material transformation condition,automatic deformation cutting

Camera follow the label transformation to graph matching.

✦Optional projector:

Projector positioning preview.

Instant Preview of Nesting Effects - convenient&fast.

✦Optional different types of conveyor tables.

JOY STAR LASER’s main products include CO2 laser marking machine, fiber laser marking machine, ultraviolet laser marking machine, CO2 laser cutting machine, fiber laser cutting machine, laser welding machine, non-standard automation and many other series. Our laser device is used in more than 100 professional fields around the world, and it is our service tenet to provide customers with the best intelligent laser application solutions.

Qualification honor

FAQ

✦How to get the most suitable machine and best price?

Please tell us the material you want to working on ? How to working on it ? Engraving ? Cutting ? Or other ? Mainly engraving or cutting?

What’s the MAX size of these material ?( length ? Width ? Thickness ?)

✦How to operate the machine ?

We will deliver English manual and video with the machine to you. If you still need our help, please contact us.

✦How we pay you ?

Please contact us, after confirm machine and optional parts to order, we will give you the link to order.

✦How can I get the sample to check you quality ?

If you want to marking sample to check the quality, we can help you do this. first you need to provide the logo or design to us, free mark samples can be provided.

✦Does the machine can be customized according to my requirements ?

Sure, we have a strong technical team and have rich experience. Our goal is to make you satisfied.

✦Can you arrange the shipment for me ?

We can arrange the shipment for our clients by sea or by air. Trading terms FOB, CIF, EXW are available.

✦How about your after-sales service?

we offer you 24 hours service phone, Email or Whatapp.

✦Quality Control:

The whole production procedure will be under regular inspection and strict quality control.

The complete machine will be tested to make sure they can work very well before being out of factory.

Our machine passed CE Certificate, meet European and American standard, were exported to more than 100 Countries.

✦How we can contact you ?

you just need to leave your contact information,like email , whatsapp on our website , we will contact you asap .

If you interest in this machine,pls feel free to contact me to get more informations.

Application industry

Suitable for computer embroidery and cutting, handbags and luggage industry, footwear industry, plush toy industry, plastic leather industry, advertising industry, packaging industry, industrial gift industry, printed clothing, printed shoe uppers, 3D flying shoe uppers, weaving patterns, embroidery Trademarks, heat transfer printing and many other industries.

Applicable materials

Leather, pu leather, suede leather, synthetic leather, cloth, plush cloth, mesh, non-woven fabrics, felt cloth, plexiglass, plastic, rubber, epoxy resin, acrylic, paper, wool, bamboo products, two-color board, ABC board, PVC board, Non-metallic materials such as fiberboard and composite materials.

| MODEL | JS-1825ST-SCCD-AUTO | |

|---|---|---|

| Processing Area(mm) | 1800mm×2500mm | |

| Laser power | 80-150W (optional)*2 | |

| Laser tube type | CO2 Glass laser tube | |

| Function | Laser Cutting | |

| Cutting speed(m/min) | 0~30m/min | |

| Laser Head | Double-Headed | |

| Minimum Form Character | Chinese Character2×2mm,Letter1×1mm | |

| Resolution Atio | < 0.01mm | |

| Location Precision | < 0.01mm | |

| Gross Power | ≈3400W | |

| Measurement (L×W×H) | 2400mm×2600mm×2750mm | |

| Cooling type | Water cooling | |

| Weight | 1000KG | |

| Sccd Camera Positioning System | Yes | |

| Power Supply | 220V/10Amax, 50Hz or 60Hz | |

| Environmental requirements | Temperature: 10-30℃ | |

| System/compatible Format | Windows 7/8/10,AI , PLT , DXF , DST ,BMP , JPG , JPEG ,PNA , TIF | |